Peterson R+ Grinder Package

Overview

With 10+ years of development, the R+ package combines the very best in engineering and innovative design to equip a typical “high speed” Peterson horizontal grinder into a “medium speed” machine, utilizing the production of a typical high speed grinder, and the protection of a slow-speed shredder.

With performance nearly doubling the output of typical slow speed shredders, R+ equipped Peterson horizontal grinders offer a solution that has high output, and superior machine protection against ungrindable materials.

Typical R+ applications include Municipal Solid Waste (MSW), Construction and Demolition (C&D) debris, chunk wood such as stumps, storm debris, railroad ties, and other materials.

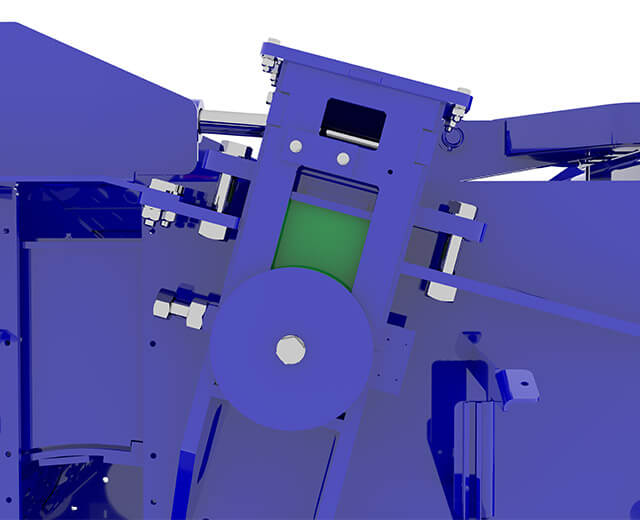

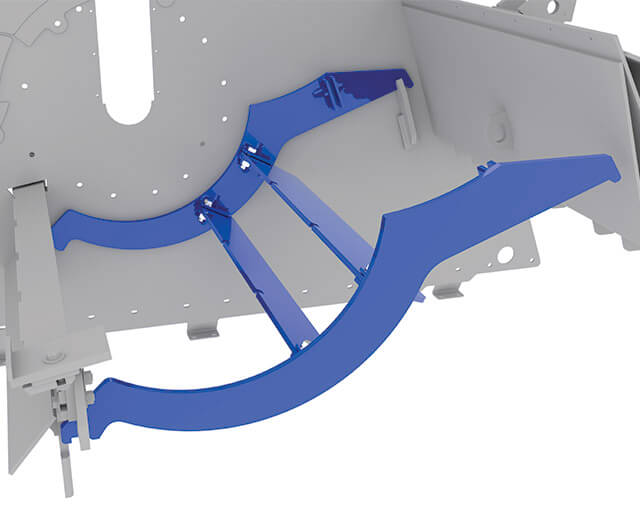

The R+ package uses a specially designed rotor with high and low bits, that turns at half the speed of our standard units. This processes material through a specialized heavy duty grate, with the high and low bits passing through the fingers, providing extensive fracturing surfaces for superior product reduction.

The R+ package utilizes Peterson’s patented Impact Release System, and Impact Cushion System to protect your investment against an ungrindable object, but has additional modifications such as a heavier duty cushion block to prevent nuisance openings, and an upgraded Impact Release System designed to perform in the harsher environment.

Other mods include more space for ground material to exit the machine, and a heavier duty discharge belt.

Already own a Peterson grinder? Your 4700, 5700, or 6700-series machine may be able to be upgraded as a package so you can take on the difficult jobs that you may have passed by before. Likewise, if you no longer need the protection of the R+ package, and your grinder is going into other applications, the R+ specific parts can be removed and replaced with standard units to change the machine back to a standard “high speed” grinder– no other machine on the market can do that!

Applications

-

![]()

Construction & Demolition Recycling

Construction and demolition recycling (C&D) is mixed material associated with construction and demolition. The material could include wood, cardboard, gypsum, plastic, metal, wire, roofing shingles, asphalt, concrete and more. By separating and recycling different materials it reduces landfill waste and associated costs, while also producing value-added products.Learn More -

![]()

Municipal Solid Waste (MSW) Recycling

Municipal solid waste (MSW) consists of everyday items we use and then throw away, such as product packaging, furniture, clothing, bottles, food scraps and newspapers. These items come from our homes, schools, businesses, etc.Learn More -

![]()

Railroad Tie Recycling

The creosote treated railroad ties are a valuable energy source, once they have been broken down into a manageable and consistent size.Learn More -

![]()

Natural Disaster Cleanup

Natural disasters such as hurricanes, tornadoes, earthquakes, fires or floods create debris that must be cleared to restore affected areas. This type of debris can be green waste (such as tree limbs), furniture, drywall or entire structures that have to be demolished and recycled.Learn More