Peterson BTS50/BTS50+ Stand-Alone Blower Unit

Overview

With a Peterson BTS50 Stand-Alone Blower Unit, you can tackle an even wider range of projects, gain productivity, and boost your profitability.

The BTS50 is available in two models, the standard BTS50 is powered by a CAT C7.1 Tier IV engine with 225 hp (167 kW), or the BTS50+, with a CAT 9.3B Tier IV engine with 335 hp (250 kW) for heavy-duty applications such as delivering light aggregate materials.

With the stand-alone power plant, the BTS50 allows you to blow material while moving the truck, which is ideal for jobs that require lots of repositioning. The BTS50’s blower unit is rated at 15 psi (1.03 bar) for typical applications of mulch or compost materials. The BTS50+ has a 20 psi (1.38 bar) blower unit, and is specifically designed for tough-to-blow applications.

Applications

-

![]()

Mulch

Organic mulch is a product that can decompose, providing nutrients to the soil over time. It can be made from a variety of materials, typically organic, but not exclusively.Learn More -

![]()

Compost

Compost is decomposed organic matter derived from either a single source material or blended for specific application performance. Materials can include garden debris, kitchen scraps, manure or yard and lawn waste.Learn More -

![]()

Playground Chips

Playground chips/mulch typically have a fibrous consistency, free of twigs, leaves and hazardous materials, no larger than two inches long and have the ability to drain water.Learn More

Downloads

Key Specifications

| Dimensions | BTS50 | BTS50+ |

|---|---|---|

| Operating Length | 1224 cm | 1224 cm |

| Operating Width | 259 cm | 259 cm |

| Operating Height | 406 cm | 406 cm |

| Loading Height | 389 cm | 389 cm |

| Stand Alone Unit Length | 942 cm | 942 cm |

| Frame Length | 815 cm | 815 cm |

| Box Length | 665 cm | 665 cm |

| Box Width | 246 cm | 246 cm |

| Box Height | 257 cm | 257 cm |

| Box Volume, Struck | 37 m3 | 37 m3 |

| Box Volume, Typical | 34 m3 | 34 m3 |

| Axle Spacing | 137 cm | 137 cm |

| Tool Box | 152 cm | 152 cm |

| Dimensions | BTS50 | BTS50+ |

|---|---|---|

| Operating Length | 40' 2" | 40' 2" |

| Operating Width | 8' 6" | 8' 6" |

| Operating Height | 13’ 4” | 13’ 4” |

| Loading Height | 12’ 9" | 12’ 9" |

| Stand Alone Unit Length | 30' 11" | 30' 11" |

| Frame Length | 26' 9" | 26' 9" |

| Box Length | 21' 10" | 21' 10" |

| Box Width | 8’ 1" | 8’ 1" |

| Box Height | 8’ 5" | 8’ 5" |

| Box Volume, Struck | 48 yds3 | 48 yds3 |

| Box Volume, Typical | 45 yds3 | 45 yds3 |

| Axle Spacing | 54” | 54” |

| Tool Box | 60" | 60" |

| Weight | BTS50 | BTS50+ |

|---|---|---|

| Weight with Typical Options | 21 546 kg | 22090 kg |

| Box Only Weight | 12 474 kg | 13 018 kg |

| Weight | BTS50 | BTS50+ |

|---|---|---|

| Weight with Typical Options | 47,500 lbs | 48,700 lbs |

| Box Only Weight | 27,500 lbs | 28,700 lbs |

| Truck Platform | BTS50 | BTS50+ |

|---|---|---|

| Chassis | any Class 8 | any Class 8 |

| Standard Chassis | Peterbilt 567 | Peterbilt 567 |

| Cab Configuration | Driver Bucket Seat & 2-Person Bench Seat | Driver Bucket Seat & 2-Person Bench Seat |

| Truck Platform | BTS50 | BTS50+ |

|---|---|---|

| Chassis | any Class 8 | any Class 8 |

| Standard Chassis | Peterbilt 567 | Peterbilt 567 |

| Cab Configuration | Driver Bucket Seat & 2-Person Bench Seat | Driver Bucket Seat & 2-Person Bench Seat |

| Power | BTS50 | BTS50+ |

|---|---|---|

| Engine | Caterpillar C7.1 Tier IV 167 kW | Caterpillar C9.3B Tier IV 250 kW |

| Fuel Tank Capacity | 435 L | 435 L |

| Hydraulic Tank Capacity | 314 L | 314 L |

| DEF Tank Capacity | 65 L | 65 L |

| Power | BTS50 | BTS50+ |

|---|---|---|

| Engine | Caterpillar C7.1 Tier IV 225 hp | Caterpillar C9.3B Tier IV 335 hp |

| Fuel Tank Capacity | 115 gal | 115 gal |

| Hydraulic Tank Capacity | 83 gal | 83 gal |

| DEF Tank Capacity | 17 gal | 17 gal |

| System Controls | BTS50 | BTS50+ |

|---|---|---|

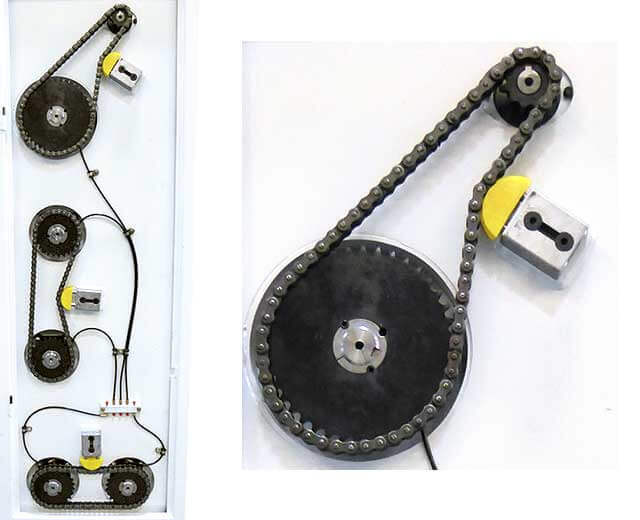

| Peterson Adaptive Feed System | Checkmark | Checkmark |

| Radio Remote | Checkmark | Checkmark |

| System Controls | BTS50 | BTS50+ |

|---|---|---|

| Peterson Adaptive Feed System |

Checkmark

|

Checkmark

|

| Radio Remote |

Checkmark

|

Checkmark

|

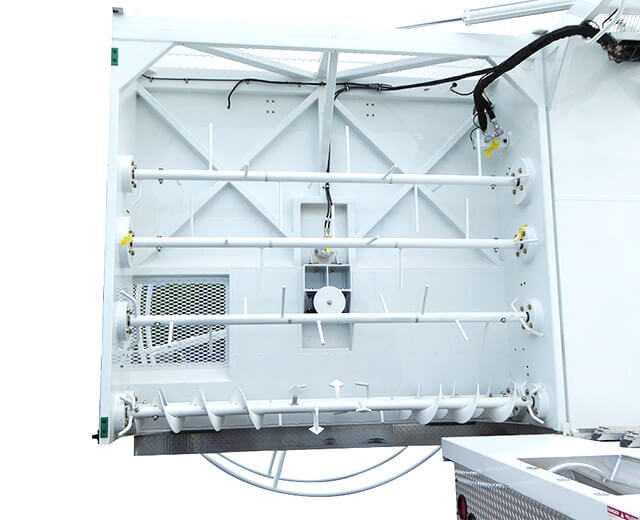

| Feed System | BTS50+ | BTS50+ |

|---|---|---|

| Floor | Stainless Steel Walking Floor | Stainless Steel Walking Floor |

| Wear Liners | Hardox 450 Steel | Hardox 450 Steel |

| Blower System | BTS50+ | BTS50+ |

| Blower | Tri-Lobe® | Tri-Lobe® |

| Blowing Pressure | 20 psi | 1.38 bar |

| Large Capacity Silencer | Intake and Discharge | Intake and Discharge |

| Feed System | BTS50 | BTS50+ |

|---|---|---|

| Floor | Aluminum Walking Floor | Stainless Steel Walking Floor |

| Wear Liners | Aluminum | Hardox 450 Steel |

| Blower System | BTS50 | BTS50+ |

| Blower | Tri-Lobe® | Tri-Lobe® |

| Blowing Pressure | 15 psi | 20 psi |

| Large Capacity Silencer | Intake and Discharge | Intake and Discharge |

| Discharge System | BTS50 | BTS50+ |

|---|---|---|

| Hose Reel | powered, holds up to 98 m | powered, holds up to 98 m |

| Discharge Hose Length | 6 m heavy-duty, 91 m standard | 6 m heavy-duty, 91 m standard |

| Hose Diameter | 127 mm, 100 mm | 127 mm, 100 mm |

| Discharge System | BTS50 | BTS50+ |

|---|---|---|

| Hose Reel | powered, holds up to 320 ft | powered, holds up to 320 ft |

| Discharge Hose Length | 20 ft heavy-duty, 300 ft standard | 20 ft heavy-duty, 300 ft standard |

| Hose Diameter | 5", 4" | 5", 4" |

| Production | BTS50 | BTS50+ |

|---|---|---|

| Discharge Volume | up to 46 m³ per hour | up to 46 m³ per hour |

| Material Weight | up to 1245 kg/m³ | up to 1601 kg/m³ |

Actual output may vary due to moisture content, material density and size, support equipment, terrain variables, and hose diameter'

| Production | BTS50 | BTS50+ |

|---|---|---|

| Discharge Volume | up to 60 yds³ | up to 60 yds³ |

| Material Weight | up to 2,100 lbs/yd³ | up to 2,700 lbs/yd³ |

Actual output may vary due to moisture content, material density and size, support equipment, terrain variables, and hose diameter'

All specifications subject to change without notice.