Peterson 6300B Drum Chipper

Overview

The 6300B Drum Chipper is suited for high volume biomass producers who have a wide variety of feed material, from logs up to 36″ (91 cm) in diameter, to brush and small feed stock.

The 6300B Drum Chipper is powered by a 1050 HP (772 kW) C27 Caterpillar engine, and has an optional Tier IV engine available. A PT Tech wet clutch has also been added to the machine. At 85,000 pounds (38,555 kg), the 6300B was designed for operations requiring high production and frequent moves between jobs.

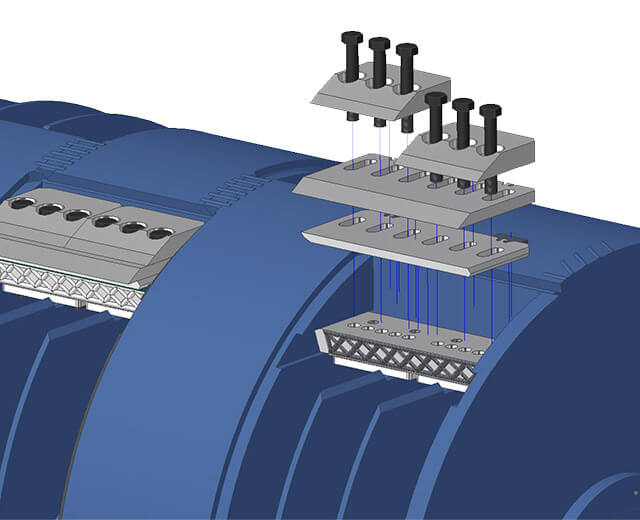

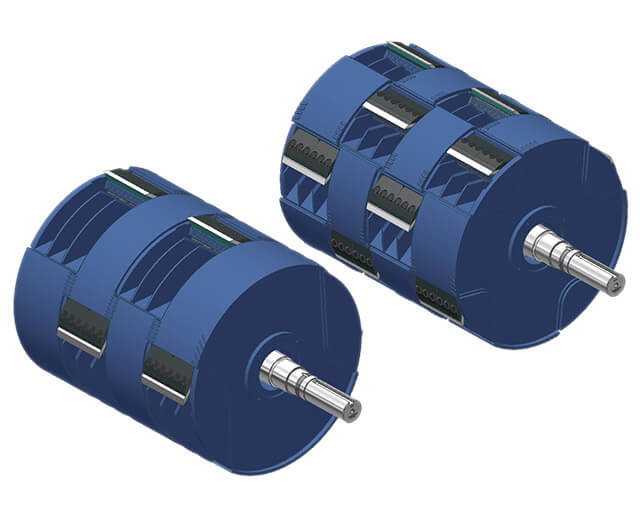

The 6300B Drum Chipper has two drum configurations, a 8-pocket drum to make standard biomass chips, or a 16-pocket drum to make microchips. An optional grate system has been redesigned to allow for adjustment from a microchip to a 1¼” chip with the same grates. Traditional Babbitt type knife systems are standard equipment, or an optional key knife system is available. Peterson’s chip accelerator system, adds load density, or throws chips well away from the machine for land clearing operations.

Applications

-

![]()

Orchard Clearout

Commercial orchards are cleared on a rotating cycle to remove lower producing or unhealthy deciduous fruit, citrus and nut trees or to replace them with a more valuable crop. New, higher-producing trees are replanted so the cycle can start again.Learn More

Downloads

Key Specifications

| Dimensions | Specifications |

|---|---|

| Operating Length | 1290 cm |

| Operating Width | 345 cm |

| Operating Height | 381 cm |

| Travel Width | 299 cm |

| Travel Length | 1 300 cm |

| Travel Height | 382 cm |

| Frame Length | 1267 cm |

| Front Ground Clearance | 122 cm |

| Rear Ground Clearance | 28 cm |

| Ground Clearance | 64 cm |

| Axle Spacing | 138 cm |

| Front to 5th Wheel | 67 cm |

| 5th Wheel to Center Axle | 948 cm |

| 5th Wheel Height | 126 cm |

| Dimensions | Specifications |

|---|---|

| Operating Length | 42' 4" |

| Operating Width | 11' 4" |

| Operating Height | 12' 6" |

| Travel Width | 9' 10" |

| Travel Length | 42' 8" |

| Travel Height | 12' 6" |

| Frame Length | 41' 7" |

| Front Ground Clearance | 4' |

| Rear Ground Clearance | 11" |

| Ground Clearance | 2' 1" |

| Axle Spacing | 4' 7" |

| Front to 5th Wheel | 2' 2" |

| 5th Wheel to Center Axle | 31' 1" |

| 5th Wheel Height | 4' 1" |

| Weights | |

|---|---|

| Machine Weight | 38 555 kg |

| 5th Wheel Weight | 16,329 kg |

| Tridem Axle Weight | 22,226 kg |

| Weights | |

|---|---|

| Machine Weight | 85,000 lbs |

| 5th Wheel Weight | 36,000 lbs |

| Tridem Axle Weight | 49,000 lbs |

| Powertrain | Specifications |

|---|---|

| Engine | Caterpillar C27 Tier IV, 772 kW |

| Clutch | PT Tech HPTO 15 FX |

| Fuel Tank Capacity | 1495 L |

| Main Hydraulic Tank Capacity | 454 L |

| System Controls | Specifications |

| Peterson Adaptive Control System | Checkmark |

| Radio Remote | Checkmark |

| Peterson+ Analytics | Checkmark |

| Powertrain | Specifications |

|---|---|

| Engine | Caterpillar C27 Tier IV, 1050 hp |

| Clutch | PT Tech HPTO 15 FX |

| Fuel Tank Capacity | 395 gallons |

| Main Hydraulic Tank Capacity | 120 gallons |

| System Controls | Specifications |

| Peterson Adaptive Control System | Checkmark |

| Radio Remote | Checkmark |

| Peterson+ Analytics | Checkmark |

| Feed System | Specifications |

|---|---|

| Feed Opening (h x w) | 91 x 145 cm |

| Feed Length | 297 cm |

| Feed Height | 127 cm |

| Feed Speed Range | up to 37 m/min |

| Feed Conveyor Width | 144 cm |

| Feed chain | 4 Sections, WDH120 |

| Compression Roll Diameter | 106 cm |

| Feed System | Specifications |

|---|---|

| Feed Opening (h x w) | 36" h x 57" w |

| Feed Length | 7' 11" |

| Feed Height | 5' 0" |

| Feed Speed Range | up to 120 ft/min |

| Feed Conveyor Width | 4' 9" |

| Feed chain | 4 Sections, WDH120 |

| Compression Roll Diameter | 42" diameter |

| Chipper | Specifications |

|---|---|

| Drum Size | 127 diameter x 152 width |

| Knife Pockets | 8 or 16 pockets (staggered) |

| Knife System | Babbitt or Key Knife™ |

| Chip Size | ( to 32 mm |

| Chipper | Specifications |

|---|---|

| Drum Size | 50" diameter x 60" width |

| Knife Pockets | 8 or 16 pockets (staggered) |

| Knife System | Babbitt or Key Knife™ |

| Chip Size | ¼" to 1 ¼" |

| Production | |

|---|---|

| Chip Output | 158 757 kg/hour |

| Production | |

|---|---|

| Chip Output | up to 175 ton/hour |

All specifications subject to change without notice.

Features

Media Gallery

| Current Item | |||||

| Compare Drum Chippers |  |

|

|

|

|

| 6300B | 4300B | 4310B | 4310B Highwalker | 6310B | |

| Standard Engine | CAT C27 Tier IV, 772 kW | CAT C18 Tier IV, 563 kW | CAT C18 Tier IV, 563 kW | CAT C18 Tier IV, 563 kW | CAT C27 Tier IV, 772 kW |

| Production* | up to 227 tonnes | 59 to 109 tonnes | 59 to 109 tonnes | 59 to 109 tonnes | up to 227 tonnes |

| Feed Opening | 145 x 91 cm | 103 x 61 cm | 103 x 61 cm | 103 x 61 cm | 145 x 91 cm |

| Weight | 38 555 kg | 23 586 kg | 26 535 kg |

26 535 kg | 39 010 kg |

*Actual production output may vary due to moisture content, material density and size, support equipment, and equipment options. Production rates are based on operating 50 minutes per hour.

| Current Item | |||||

| Compare Drum Chippers |  |  |  |  |  |

| 6300B | 4300B | 4310B | 4310B Highwalker | 6310B | |

| Standard Engine | CAT C27 Tier IV, 1050 hp | CAT C18 Tier IV, 755 hp | CAT C18 Tier IV, 755 hp | CAT C18 Tier IV, 755 hp | CAT C27 Tier IV, 1050 hp |

| Production* | up to 250 tons | 60 to 120 tons | 60 to 120 tons | 60 to 120 tons | up to 250 tons |

| Feed Opening | 57” x 36” | 40” x 24” | 40” x 24” | 40” x 24” | 57” x 36” |

| Weight | 85,000 lbs | 52,000 lbs | 58,500 lbs | 58,500 lbs | 86,000 lbs |

*Actual production output may vary due to moisture content, material density and size, support equipment, and equipment options. Production rates are based on operating 50 minutes per hour.